The FDA Final Rule on Requirements for Additional Traceability Records for Certain Foods, also called the Food Traceability Final Rule, creates new traceability requirements for food on the FDA’s Food Traceability List (FTL). Foods included on the FTL consist of cheeses, fresh produce and fish/seafood. These requirements tied to the record-keeping of traceability data are complementary to requirements that are already set in place by the FSMA. According to the FDA, the new traceability requirements established in the food traceability final rule will:

FDA food traceability requirements: How will FSMA change the FDA's recordkeeping requirements

The U.S. Food and Drug Administration (FDA) has recently established new requirements for food traceability, meaning the ability to trace the movement of food products through the supply chain from “farm to fork”. These changes mean new rules for compliance. QR codes on food items at all stages of transport and delivery are the recommended response.

“…allow for faster identification and rapid removal of potentially contaminated food from the market, resulting in fewer foodborne illnesses and/or deaths.”

This article covers:

- Why is food traceability important

- How is the FSMA related to the FDA?

- What is the Food Traceability List

- FDA Food Traceability Final Rule: How does it work?

- FDA Food Traceability Final Rule: When do I need to comply?

- Hazard Analysis and Risk-Based Preventive Controls (HARPC)

- Is there a difference between food traceability and product tracing?

- How can companies be in compliance with the FSMA and FDA requirements?

- What is the process for implementing QR codes on food products?

- QR code packaging: is there more to it?

- A summary of the FSMA FDA regulation requirements

Why is food traceability important?

A recent increase in illnesses and deaths due to contaminated food has prompted the latest FDA established requirements for food traceability. These requirements are designed to help prevent foodborne illness outbreaks and better protect public health. For businesses that sell food, these new requirements will form the basis of a compliance plan. While this is a serious issue for food importers, exporters, and other related businesses, the stakes go beyond just business. According to the Center for Disease Control and Prevention, 48 million people in the U.S. become ill every year due to foodborne illness. This includes 128,000 that are hospitalized and almost 3,000 people that die from those illnesses.

How is the FSMA related to the FDA?

The FDA response to the increasing problem with foodborne illness is the new food traceability requirements. These requirements have taken the form of the Food Safety Modernization Act (FSMA), first signed into law in 2011. The FSMA is a comprehensive overhaul of the United States’ food safety system and aims to prevent foodborne illness outbreaks by focusing on preventing contamination at the source. This approach is in contrast to investing more in a system that deals with contamination after a problem is discovered. Prevention is the key concept in these new regulations.

What is the Food Traceability List?

The Food Traceability List is a list of foods designated by the FDA for which additional recordkeeping is required as a prophylactic for public health. The food and ingredients on the list are categorized as more likely to be contaminated than those not on the list. The foods on this list are accompanied by a ranking according to their potential risk to public health. The FDA ranking factors are:

- Frequency of outbreaks and occurrences of illnesses

- Severity of illness

- Likelihood of contamination

- The potential for pathogen growth, with consideration of shelf life

- Manufacturing process contamination probability and industry-wide intervention

- Consumption rate and amount consumed

- Cost of associated illness

Unsurprisingly, most of the foods on this list are either fresh foods, or animal based products.

The Food Traceability List includes the following (updated Jan 17th, 2023):

- Cheeses, other than hard cheeses

- Shell eggs

- Nut butters

- Cucumbers (fresh)

- Herbs (fresh)

- Leafy greens (fresh)

- Melons (fresh)

- Peppers (fresh)

- Sprouts (fresh)

- Tomatoes (fresh)

- Tropical tree fruits (fresh)

- Fruits (fresh-cut)

- Vegetables other than leafy greens (fresh-cut)

- Finfish (fresh and frozen)

- Smoked finfish (refrigerated and frozen)

- Crustaceans (fresh and frozen)

- Molluscan shellfish, bivalves (fresh and frozen)

- Ready-to-eat deli salads (refrigerated)

The FDA reports that this list will be updated or changed in the future according to new discoveries and developments. A more extensive version of this list, with additional descriptions, is available on the official FDA Food Traceability List webpage.

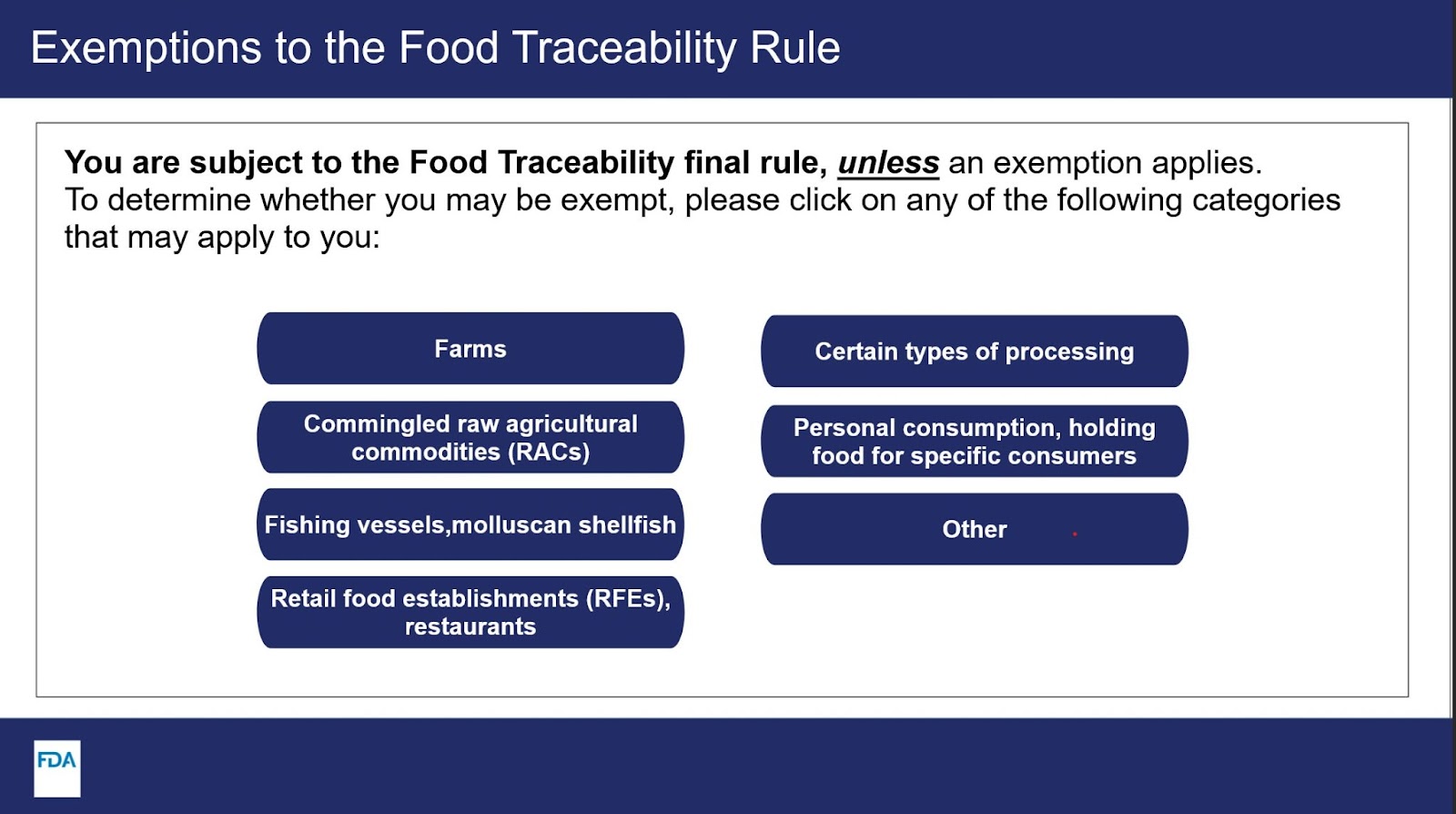

A simple program has been conveniently made available by the FDA to identify exceptions from the Food Traceability Final rule. This web dialogue is also available for your reference on their website here.

FDA Food Traceability Final Rule: How does it work?

The Food Traceability Final Rule requires traceability data association for food on the Food Traceability List (FTL). This applies to foreign and domestic food manufacturers, food processors, packagers, or any domestic or foreign food companies selling or distributing food that is meant to be consumed in the U.S. and that includes ingredients found on the FTL.

There are two key parts to the Food Traceability final rule. Firms must:

- Maintain records containing Key Data Elements (KDE’s)

- Associate those records with Critical Tracking Events (CTE’s)

Any person or company involved in the supply chain process must ensure maintenance and provision of Key Data Elements (KDE) to supply chain partners and the FDA. The FDA has specified the kind of data that is most critical as Critical Tracking Events (CTE). These Critical Tracking Events are meant to ensure a higher level of traceability throughout the supply chain, which in term is expected to result in a higher level of food safety. The KDE’s and CTE’s vary per type of product and supply chain activity. There is not one guideline that fits all foods on the FTL. You can learn more about the exact KDE’s required for each CTE on the FDA website here.

In the event of a data request, Key Data Elements must be provided to the FDA within 24 hours or within a reasonable timeframe that the FDA agrees on.

FDA Food Traceability Final Rule: When do I need to comply?

The compliance date for all corporations affected by this regulation is January 20th, 2026. That may seem like a long way out, but remember that there is an extensive list of requirements that multiple companies must adhere to. Next to that, these companies must share information with each other throughout the supply chain. According to the FDA: “the most effective and efficient way to implement the rule is to have all persons subject to the requirements come into compliance by the same date.” This means that the FDA is giving enough time for everyone to comply simultaneously.

Hazard Analysis and Risk-Based Preventive Controls (HARPC)

Food facilities are also now required to have a Hazard Analysis and Risk-Based Preventive Controls (HARPC) plan in place. This plan identifies potential hazards that could occur at each stage of the production process, and outlines the preventive controls for preventing those hazards. This includes controls for the safety of the food and its ingredients, as well as controls for the facility and the equipment used in the production process. The HARPC plan already came into effect in 2011, and was expanded to the greater food industry in 2015. While it is closely tied to the Food Traceability Final Rule, with the same goal of identifying dangerous foods and other food hazards, it is nevertheless an important part of the food traceability reform.

Is there a difference between food traceability and product tracing?

FDA requirement for food facilities to implement a product tracing system includes the legal requirement to trace a product back to its source within a reasonable amount of time. Identification of the specific lot or batch of the product is necessary. These are the same features and requirements that you’ll find in product traceability or product tracing. The only difference is the item being traced and the reporting requirements.

How can companies be in compliance with the FSMA and FDA requirements?

The recommended way for companies to meet traceability requirements is through the use of QR codes. QR codes, or quick response codes, are barcodes that can be scanned with a smartphone or other device to access information about a product. By using serialized QR codes, one can associate information for specific products, or batches or products to a QR code. When QR codes are scanned, data about the product can be conveyed in an online format, accessible by anyone who scans the QR code. This digital display of information is beneficial for both consumers and companies.

From the company or provider’s side, inspectors or other authorized users can scan product or batch level codes to update the Key Data Elements (KDE’s) record. Critical Tracking Events too can be updated along the value chain. Because these QR codes are placed on food packaging or on product labels, they are the most convenient way to provide information about the product’s origin, ingredients, and other important details to end consumers once they’ve arrived at retail.

All of these QR code interactions, inspector level and end customer level, creates an aggregation of data that can be easily provided to the FDA and other regulatory agencies as needed. In the event of a foodborne illness outbreak, not only will the companies using this system be in compliance, but authorities can reference basic yet powerful details related to origin or processing locations in mere instants.

What is the process for implementing QR codes on food products?

The process for implementing QR codes on products with Scantrust typically involves the following steps:

- Consultation: food companies should prepare a list of their specific needs and goals for implementing QR codes on their products. The focus should be on requirements that are in addition to company responsibility as part of the FSMA. A summary list of the requirements for the FSMA are found later in this article. Current traceability processes and identifying any potential challenges or areas for improvement should be prepared.

- Customization: Based on this information, the consultation project team will create a customized QR code solution for your company. This may include adding additional features to satisfy any additional requirements, such as copy detection, but can be as simple as setting up the code uploads and preparation for variable data printing. The information that will be included in the code would be determined at this stage.

- Implementation: Once the customized QR code solution has been developed, the project team will assist in implementation with printing to products or labels. This may include just printing the QR code onto labels or packaging, or it may extend to integrating the solution with unique production processes or systems such as ERP, CRM, etc.

- Tracking and monitoring: Tracking and monitoring systems will be live with the items in-market and the scanning of QR codes on products. Inspectors and end-customers will have easy access to required information and your company can rest easy knowing you are in compliance with the FDA FSMA.

Companies have several options when looking for a vendor providing a process for implementing QR codes on products. Be sure that you invest in a system that is obviously designed to be seamless and straightforward, with a focus on helping you meet your traceability and authenticity goals and minimizing disruption to your business.

QR code packaging: is there more to it?

QR codes are a key element to food traceability schemes, but they also have other benefits beyond basic food safety. For example, they can be used to provide consumers with additional information about the safety and quality of a product. This can help to build trust and confidence in the product and brand, and can also help to ensure that consumers are making informed decisions about the food they are purchasing. When a product is recalled due to contamination, the QR code landing page destination can be updated to reflect this information. This can prevent consumers from accidentally purchasing a potentially dangerous product.

While QR codes can be an effective tool for improving food traceability and safety, it is important for companies to properly implement and maintain their use. This includes ensuring that the codes are placed in a visible location on the product, and that the information provided is accurate and up-to-date. In order to be in compliance with FDA food traceability requirements, companies must also ensure that their traceability systems are able to provide the related traceability information in a timely manner. This includes being able to trace a product back to its source within a reasonable amount of time, and being able to identify the corresponding product lot or batch.

QR codes on packaging are the most basic part of a system documenting any changes made to products or production processes and associating those changes with packaging. This can include changes to ingredients, the packaging itself, or any other aspect of the product. By keeping track of these changes, companies can ensure that their products meet any necessary requirements and reassure themselves that they are in compliance with regulations.

A summary of the FSMA FDA regulation requirements

The main component for being in compliance with the FSMA is a Hazard Analysis and Risk-Based Preventive Controls (HARPC) plan: This plan identifies potential hazards that could occur at each stage of the production process, and outlines the preventive controls that will be put in place to prevent those hazards. Several components can be provided for or managed entirely using a QR code management system:

- Traceability system: This system should be able to trace a product back to its source within a reasonable amount of time, and should be able to identify the specific lot or batch of the product.

- Sanitation preventive controls: These controls are designed to prevent food contamination from unsanitary conditions in the facility. This may include requirements for cleaning and sanitizing equipment and surfaces, as well as training employees on proper food handling practices.

- Recall plan: Companies are required to have a plan in place for recalling products in the event of a contamination or safety issue. This plan should outline the steps that will be taken to recall the product, as well as how to notify the public about the recall.

- Record-keeping: Companies are required to maintain records of their food safety practices, including the preventive controls implemented, any inspections or testing conducted, and any corrective actions taken. These records should be easily accessible and available for review by the FDA.

Next to the HARPC plan, Companies involved in the production of food on the Food Traceability List are additionally required to comply with the Food Traceability Final Rule. The FSMA requires these food facilities to have comprehensive food safety practices in place, including preventive controls, product traceability systems, and recall plans. By implementing these features, companies can help to ensure the safety of the food they produce and protect the public health while being in compliance with mandatory regulations. QR codes and an experienced QR code manager system integrator will make this process easy while ensuring your company is in compliance.